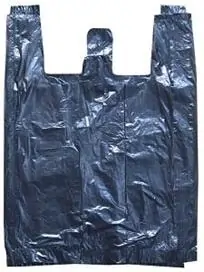

The nylon cutting and sealing business in Nigeria is a thriving and dynamic industry that caters to the diverse packaging needs of businesses and consumers alike. Nigeria, with its large population and growing economy, presents a significant demand for various types of nylon products. From shopping bags to packaging materials, the versatility of nylon makes it an essential component in numerous industries.

The Nigerian market offers a wide range of nylon types to meet the diverse packaging requirements of different sectors. These include low-density polyethylene (LDPE) bags, high-density polyethylene (HDPE) bags, polyvinyl chloride (PVC) bags, shrink wraps, and more. Each type of nylon has its own unique characteristics and applications, serving specific purposes in various industries such as retail, food, pharmaceuticals, and manufacturing.

The diversity in nylon types is driven by the diverse needs of consumers and businesses across the country. Shopping bags made from LDPE or HDPE are widely used in supermarkets, grocery stores, and retail outlets, providing a convenient and hygienic solution for packaging goods. PVC bags are commonly utilized for packaging garments, shoes, and other durable products, offering enhanced protection and visibility. Shrink wraps find their utility in bundling and securing products, ensuring safety during transportation and storage.

The demand for nylon products in Nigeria is consistently high, driven by the growth of industries, urbanization, and an increasing consumer culture. As the population continues to expand and disposable incomes rise, the need for packaging solutions escalates, presenting a significant opportunity for entrepreneurs to venture into the nylon cutting and sealing business.

The Nigerian market also witnesses a growing awareness of sustainable and eco-friendly packaging solutions. This shift in consumer preferences has led to an increasing demand for biodegradable and recyclable nylon materials. Entrepreneurs can tap into this segment by offering environmentally friendly options and positioning their business as a sustainable packaging solution provider.

Market Research and Feasibility Study:

Before starting a nylon cutting and sealing business in Nigeria, conducting thorough market research and a feasibility study is crucial. This process will help you understand the dynamics of the nylon market, assess demand and competition, and determine the profitability of each nylon category. Additionally, gaining insights into customer preferences and requirements will enable you to align your business offerings accordingly.

Comprehensive Market Research:

- Identify and analyze the various nylon types available in the Nigerian market, such as LDPE bags, HDPE bags, PVC bags, shrink wraps, and others.

- Evaluate the current market size and growth potential for each nylon category.

- Explore industry trends, market dynamics, and future projections to anticipate demand patterns.

Assessing Demand and Competition:

- Determine the demand for each nylon type by considering factors like industry demand, consumer behavior, and market segmentation.

- Identify potential customers, including retailers, manufacturers, distributors, and end consumers, and understand their specific requirements.

- Evaluate the competitive landscape by identifying existing players, their market share, pricing strategies, and product offerings.

Profitability Analysis:

- Estimate the production costs, including raw materials, labor, machinery, utilities, and overhead expenses, for each nylon category.

- Analyze the pricing structure and market demand to determine the potential profit margins.

- Consider economies of scale and production efficiency to assess long-term profitability.

Understanding Customer Preferences and Requirements:

- Conduct surveys, interviews, or focus groups to gather insights into customer preferences, packaging needs, and buying behavior.

- Identify specific requirements and expectations regarding quality, durability, size, design, and sustainability.

- Incorporate customer feedback into your product development and marketing strategies.

By conducting comprehensive market research and a feasibility study, you will be equipped with valuable information to make informed decisions for your nylon cutting and sealing business. This research will help you identify the most promising nylon categories, understand customer preferences, and tailor your business offerings to meet market demands effectively. It will also enable you to anticipate challenges, identify unique selling points, and develop a competitive advantage in the Nigerian nylon market.

Business Plan:

To establish a successful nylon cutting and sealing business in Nigeria, it is essential to create a well-defined business plan tailored to the specific dynamics of the Nigerian market. This plan will serve as a roadmap for your business, outlining the nylon types you intend to produce and sell, as well as strategies for pricing, distribution, and marketing.

Product Selection and Differentiation:

- Identify the specific nylon types you plan to produce and sell based on your market research and customer preferences.

- Consider the demand, profitability, and competition for each nylon category.

- Differentiate your products by offering unique features, customization options, or environmentally friendly alternatives.

Pricing Strategy:

- Develop a pricing strategy based on production costs, market demand, and competitor pricing.

- Consider factors such as raw material costs, labor expenses, overheads, and desired profit margins.

- Conduct regular pricing evaluations to ensure competitiveness while maintaining profitability.

Distribution Channels:

- Determine the most effective distribution channels for your nylon products, considering the target market and customer preferences.

- Explore options such as direct sales, wholesalers, distributors, or online platforms.

- Build relationships with reliable distributors or retailers to expand your market reach.

Marketing and Promotion:

- Develop a comprehensive marketing strategy to create awareness and generate demand for your nylon products.

- Identify target customer segments and tailor your marketing messages accordingly.

- Utilize a mix of traditional marketing (print, radio, TV) and digital marketing channels (website, social media, email campaigns) to reach a wide audience.

Branding and Positioning:

- Establish a strong brand identity that reflects the unique value proposition of your nylon products.

- Develop a compelling brand message and positioning that resonate with your target market.

- Consistently communicate your brand values through packaging, advertising, and customer interactions.

Sales and Customer Relationship Management:

- Outline strategies for acquiring and retaining customers in the competitive nylon market.

- Implement effective sales techniques and customer relationship management practices.

- Provide exceptional customer service and address customer feedback to build long-term relationships.

Financial Projections:

- Prepare detailed financial projections, including startup costs, revenue forecasts, and expense estimates.

- Consider factors such as equipment costs, raw material expenses, marketing expenses, and working capital requirements.

- Monitor and review financial performance regularly to make informed business decisions.

By creating a comprehensive business plan, you will have a clear roadmap to guide your nylon cutting and sealing business in Nigeria. This plan will help you outline the specific nylon types to produce and sell, develop pricing strategies, establish distribution channels, and effectively promote your products in the market. Regularly review and update your business plan to adapt to changing market conditions and ensure the long-term success of your business.

Legal and Regulatory Requirements:

When starting a nylon cutting and sealing business in Nigeria, it is crucial to familiarize yourself with the legal and regulatory framework governing nylon production and sale. Ensuring compliance with these requirements will help you establish a legitimate and trustworthy business. Here are the key steps to consider:

Research and Understand the Regulations:

- Research and study the relevant laws, regulations, and guidelines governing nylon production and sale in Nigeria.

- Familiarize yourself with industry-specific regulations related to packaging materials and manufacturing processes.

- Stay updated on any changes or updates in the legal framework to ensure ongoing compliance.

Business Registration:

- Register your business with the appropriate government agencies, such as the Corporate Affairs Commission (CAC).

- Choose a business name that reflects your brand identity and complies with the naming regulations set by the CAC.

- Follow the registration process, which typically involves submitting necessary documents, paying registration fees, and obtaining a Certificate of Incorporation.

Permits and Licenses:

- Identify the permits and licenses required for operating a nylon cutting and sealing business.

- Contact relevant government agencies, such as the National Agency for Food and Drug Administration and Control (NAFDAC) or the Standards Organization of Nigeria (SON), to inquire about specific requirements.

- Obtain the necessary permits and licenses related to the production, packaging, and labeling of nylon products.

Quality Certifications:

- Consider obtaining relevant quality certifications to assure customers of the safety and quality of your nylon products.

- Standards such as the Nigerian Industrial Standard (NIS) or ISO certifications can enhance your credibility in the market.

- Adhere to the specified quality control measures and participate in audits to maintain compliance.

Environmental Regulations:

- Ensure compliance with environmental regulations and guidelines in the nylon production process.

- Implement measures for waste management, recycling, and disposal of production byproducts in an environmentally responsible manner.

- Seek guidance from environmental agencies to understand and fulfill your obligations.

Health and Safety Compliance:

- Prioritize the health and safety of your employees by implementing safety protocols and providing the necessary protective equipment.

- Comply with occupational health and safety regulations to ensure a safe working environment.

- Conduct regular inspections and train employees on safety procedures.

Intellectual Property Rights:

- Protect your intellectual property, such as brand names, logos, and designs, by registering trademarks or patents, if applicable.

- Consult with intellectual property lawyers to understand the legal requirements and procedures for protecting your intellectual assets.

By familiarizing yourself with the legal and regulatory requirements, registering your business, obtaining necessary permits and licenses, and adhering to quality and environmental standards, you can establish a compliant and trustworthy nylon cutting and sealing business in Nigeria. It is advisable to consult with legal professionals or relevant government agencies to ensure complete compliance with the prevailing regulations.

Location and Infrastructure:

Choosing the right location for your nylon cutting and sealing business in Nigeria is crucial for efficient operations and access to key resources. Consider the following factors when selecting a location and setting up the necessary infrastructure:

Proximity to Raw Materials:

- Choose a location that is in close proximity to suppliers of raw materials required for nylon production, such as LDPE, HDPE, PVC, or other materials specific to your product line.

- Access to raw materials reduces transportation costs and ensures a steady supply for uninterrupted production.

Transportation and Logistics:

Consider the transportation infrastructure in the chosen location, including roads, ports, and airports.

Ensure easy access to transportation routes for both inbound raw materials and outbound finished products.

Evaluate the availability of reliable logistics services to facilitate the efficient distribution and delivery of your nylon products.

Target Market:

- Analyze the geographical reach and distribution patterns of your target market.

- Consider locating your business in an area that provides easy access to your target customers, such as industrial zones, commercial centers, or areas with high population density.

- Evaluate the competition in the selected area to ensure your business can capture a sufficient market share.

Utilities and Amenities:

- Ensure the availability of necessary utilities, such as electricity, water, and telecommunications infrastructure, in the chosen location.

- Assess the reliability and cost of utilities to avoid disruptions in production.

- Consider other amenities that may be important for your business, such as proximity to banking services, packaging suppliers, or maintenance and repair facilities.

Facility Size and Layout:

- Determine the space requirements for your nylon cutting and sealing operations, considering factors like production machinery, storage areas, offices, and employee facilities.

- Plan the layout of your facility to optimize workflow and ensure smooth operations.

- Consider scalability and future expansion when selecting the facility size to accommodate potential business growth.

Security and Safety:

- Choose a location that provides a safe and secure environment for your employees, equipment, and inventory.

- Assess the local security situation and consider implementing security measures, such as surveillance systems and access controls, if necessary.

- Ensure compliance with safety regulations and create a safe working environment for your employees.

Cost Considerations:

- Evaluate the overall cost implications of the chosen location, including rent or purchase costs, utilities, taxes, and labor expenses.

- Balance the costs with the potential benefits of the location, such as access to resources, market proximity, and transportation efficiencies.

By carefully considering these factors, you can select a suitable location for your nylon cutting and sealing business in Nigeria. A well-chosen location with the necessary infrastructure will contribute to efficient operations, cost-effectiveness, and proximity to key resources, ultimately supporting the success and growth of your business.

Equipment and Materials:

To successfully operate a nylon cutting and sealing business in Nigeria, it is important to identify the essential equipment needed for the production process, evaluate options for acquiring machinery, and ensure the availability of high-quality raw materials. Consider the following points:

Equipment for Nylon Cutting and Sealing:

- Identify the specific machinery required for nylon cutting and sealing operations, such as cutting machines, sealing machines, heat guns, printing machines (if applicable), and packaging equipment.

- Assess the production capacity, efficiency, and reliability of different equipment options to meet your business requirements.

- Consider factors such as ease of operation, maintenance requirements, and compatibility with different types of nylon materials.

Purchasing or Leasing Machinery:

- Evaluate the financial feasibility of purchasing versus leasing equipment based on your budget and long-term business goals.

- If purchasing, research reputable suppliers or manufacturers that offer reliable machinery suitable for nylon cutting and sealing.

- Compare prices, warranties, after-sales support, and maintenance services offered by different suppliers to make an informed decision.

- If leasing, explore leasing options provided by equipment rental companies or leasing agencies and assess the terms and costs involved.

Raw Materials:

- Identify reliable suppliers of high-quality raw materials required for nylon production, such as LDPE, HDPE, PVC, or other specific materials for your product line.

- Conduct thorough research to find suppliers that offer consistent quality, competitive pricing, and timely delivery.

- Consider establishing long-term relationships with suppliers to ensure a reliable supply chain for uninterrupted production.

- Monitor market trends and developments in raw material pricing to optimize procurement costs.

Quality Control:

- Implement a robust quality control process to ensure that the raw materials meet the required standards and specifications.

- Conduct regular inspections and testing to verify the quality and consistency of the raw materials.

- Establish quality control measures for the finished nylon products to ensure they meet customer expectations and industry standards.

Backup and Spare Parts:

- Maintain an inventory of critical spare parts for your machinery to minimize downtime in the event of equipment failure.

- Establish relationships with authorized service centers or technicians who can provide prompt repairs and maintenance support when needed.

- Implement preventive maintenance schedules to prolong the lifespan of your machinery and minimize disruptions in production.

Safety Equipment:

- Provide appropriate safety equipment for your employees, such as gloves, goggles, and protective clothing, to ensure a safe working environment.

- Comply with occupational health and safety regulations and train employees on proper equipment handling and safety protocols.

By identifying the necessary equipment, evaluating purchase or lease options, and ensuring a reliable supply of high-quality raw materials, you can set up a well-equipped nylon cutting and sealing business in Nigeria. The use of reliable machinery and high-quality materials will contribute to efficient production processes, consistent product quality, and customer satisfaction.

Staffing and Training:

To effectively run your nylon cutting and sealing business in Nigeria, it is important to determine the required workforce, hire skilled personnel or provide training, and effectively manage and motivate your team. Consider the following aspects:

Workforce Planning:

- Assess the different roles and responsibilities required for your business operations, such as machine operators, quality control personnel, packaging staff, administrative personnel, and sales representatives.

- Determine the optimal number of employees based on your production capacity, workload, and business objectives.

- Consider the skills and qualifications needed for each position to ensure a well-rounded team.

Hiring Skilled Personnel:

- Advertise job openings through appropriate channels, such as online job portals, local job boards, or referrals.

- Conduct thorough interviews and screenings to assess the qualifications, experience, and skills of potential candidates.

- Prioritize candidates with relevant experience in the nylon industry or similar manufacturing environments.

- Consider the cultural fit and attitude of candidates, as teamwork and a positive work environment are essential for productivity and success.

Employee Training and Development:

- Provide comprehensive training programs for new hires to familiarize them with the nylon cutting and sealing processes, machinery operation, quality control standards, and safety procedures.

- Invest in ongoing training and professional development to enhance the skills and knowledge of your employees.

- Cross-train employees in different roles to ensure flexibility and optimize operational efficiency.

- Stay updated on industry trends and technological advancements, and provide relevant training to keep your team competitive.

Effective Team Management:

- Establish clear communication channels and reporting structures to facilitate effective coordination and information flow within the team.

- Set performance expectations, goals, and targets for each employee, and regularly monitor their progress.

- Provide constructive feedback and recognition to motivate and encourage your team members.

- Foster a positive work environment by promoting teamwork, open communication, and a culture of continuous improvement.

Employee Motivation and Retention:

- Implement performance-based incentive programs or recognition schemes to motivate and reward exceptional performance.

- Provide opportunities for career growth and advancement within your organization.

- Encourage employee feedback and actively address any concerns or issues to maintain a high level of job satisfaction.

- Foster a positive work-life balance by promoting employee well-being and implementing work policies that support a healthy work environment.

Compliance with Employment Laws:

- Familiarize yourself with the relevant labor laws and regulations in Nigeria to ensure compliance with employment practices, benefits, working hours, and employee rights.

- Establish clear policies and procedures related to employee contracts, leave, benefits, and disciplinary actions.

- Consult with legal professionals or HR experts to ensure adherence to labor laws and regulations.

By carefully considering your workforce requirements, hiring skilled personnel or providing necessary training, and effectively managing and motivating your team, you can create a capable and motivated workforce for your nylon cutting and sealing business in Nigeria. A well-trained and motivated team is crucial for ensuring smooth operations, maintaining product quality, and achieving business success.

Marketing and Promotion:

To effectively promote your nylon cutting and sealing business in Nigeria, it is essential to develop a comprehensive marketing strategy that reaches your target audience, creates a strong brand identity, and utilizes both traditional and digital marketing channels. Consider the following steps:

Define Your Target Audience:

- Identify the specific market segments or customer groups that are most likely to be interested in your nylon products.

- Conduct market research to understand their demographics, preferences, buying behaviors, and needs.

- Develop buyer personas to guide your marketing efforts and tailor your messages accordingly.

Develop a Marketing Strategy:

- Set clear marketing objectives that align with your business goals, such as increasing brand awareness, generating leads, or boosting sales.

- Determine the marketing mix that best suits your target audience, considering both traditional and digital channels.

- Create a marketing budget that allows for the effective allocation of resources across different marketing activities.

Brand Identity and Messaging:

- Develop a strong brand identity that reflects the values, quality, and unique selling propositions of your nylon products.

- Create a compelling brand story and messaging that resonate with your target audience.

- Design a visually appealing logo, packaging, and marketing materials that are consistent with your brand identity.

Traditional Marketing Channels:

- Utilize traditional marketing channels to reach your target audience, such as print advertisements in relevant industry publications, billboards, radio, and television.

- Participate in trade shows, exhibitions, and industry events to showcase your nylon products and establish business connections.

- Leverage local networks and partnerships to expand your reach and enhance brand visibility.

Digital Marketing Channels:

- Build a professional website that provides information about your nylon products, showcases your brand, and facilitates online inquiries and purchases.

- Utilize social media platforms, such as Facebook, Instagram, and LinkedIn, to engage with your target audience, share product updates, and run targeted ad campaigns.

- Consider email marketing campaigns to nurture leads, share product information, and offer promotional discounts.

Implement content marketing strategies, such as blogging or creating video tutorials, to establish your expertise and attract organic traffic to your website.

Customer Relationship Management:

- Implement a customer relationship management (CRM) system to manage customer interactions, track leads, and analyze customer data for personalized marketing efforts.

- Foster positive customer relationships through excellent customer service, prompt responses to inquiries, and addressing customer feedback and concerns.

Monitor and Analyze Results:

- Track the effectiveness of your marketing campaigns using relevant metrics, such as website traffic, leads generated, conversion rates, and sales.

- Make data-driven decisions by analyzing customer insights and feedback to refine your marketing strategies and improve ROI.

Remember to continuously adapt and refine your marketing efforts based on market trends, customer feedback, and the performance of different marketing channels. By developing a well-rounded marketing strategy that combines traditional and digital channels, you can effectively reach your target audience, build brand awareness, and drive the success of your nylon cutting and sealing business in Nigeria.

Operational Challenges and Solutions:

Operating a nylon cutting and sealing business in Nigeria comes with its own set of challenges. Identifying and addressing these challenges is crucial for maintaining smooth operations and ensuring business success. Consider the following common challenges and strategies to overcome them:

Production Challenges:

1. Insufficient production capacity: Assess your production capacity regularly to ensure it meets market demand. Consider investing in additional machinery or expanding your production facilities as needed.

2. Quality control issues: Implement robust quality control measures to maintain consistent product quality. Regularly inspect and test finished products to identify and address any defects or deviations from specifications.

3. Equipment breakdowns: Conduct regular maintenance of machinery to minimize the risk of breakdowns.

4 .Maintain a stock of essential spare parts and establish relationships with service technicians to ensure prompt repairs.

Supply Chain Management:

- Raw material availability: Establish strong relationships with reliable suppliers to ensure a consistent supply of high-quality raw materials. Monitor market trends and establish backup suppliers to mitigate any disruptions.

- Logistics and transportation: Optimize your supply chain by evaluating transportation options, negotiating favorable contracts with logistics providers, and maintaining efficient inventory management practices.

- Inventory management: Implement inventory control measures to avoid stockouts or excess inventory.

- Regularly review demand forecasts and adjust procurement quantities accordingly.

Customer-related Challenges:

- Meeting customer demands: Regularly communicate with customers to understand their requirements and preferences. Tailor your products and services to meet their needs and provide excellent customer service.

- Handling customer complaints: Develop a customer complaint handling process to address any issues promptly and effectively. Train your staff on handling customer concerns and strive to resolve complaints to maintain customer satisfaction.

Operational Efficiency Improvement:

- Continuous process improvement: Regularly evaluate your production processes to identify areas for improvement. Implement Lean or Six Sigma methodologies to streamline operations and eliminate waste.

- Employee training and engagement: Invest in training programs to enhance employee skills and knowledge.

- Encourage employee involvement in process improvement initiatives to foster a culture of continuous improvement.

- Technology adoption: Explore technological solutions that can enhance operational efficiency, such as automation, data analytics, or inventory management software. Assess the feasibility and potential benefits of implementing such technologies in your operations.

Adaptation to Market Changes:

- Stay updated on market trends, customer preferences, and industry developments. Continuously monitor competitors and adapt your products and services to remain competitive.

- Flexibility in production: Maintain flexibility in your production processes to accommodate changes in customer demands or market trends. Consider offering customizable or personalized options to meet varying customer requirements.

Effective Communication and Collaboration:

Foster open and transparent communication within your organization to facilitate effective collaboration between different departments. Encourage cross-functional teams to address challenges collectively and share knowledge and expertise.

By proactively addressing operational challenges, implementing appropriate strategies, and continuously improving operational efficiency, you can overcome obstacles and enhance the performance of your nylon cutting and sealing business in Nigeria. Regularly assess and adapt your operations to meet changing market demands, customer expectations, and industry trends. This approach will help you stay competitive and achieve long-term success.

Scaling and Diversification:

As your nylon cutting and sealing business in Nigeria grows and matures, you may consider scaling up your operations and diversifying your offerings to capture new opportunities. Explore the following strategies to expand your business, introduce additional product lines or value-added services, and build long-term partnerships and customer relationships:

Market Expansion:

- Identify new geographic markets within Nigeria where there is a demand for nylon products. Conduct market research to understand the needs, preferences, and purchasing power of customers in those areas.

- Develop targeted marketing and distribution strategies to reach and engage potential customers in these new markets.

- Consider partnerships with local distributors or retailers to expand your reach and penetrate new market segments.

Product Line Expansion:

- Assess market demand and identify complementary product lines that align with your existing nylon cutting and sealing business. This could include related packaging materials, specialized nylon products, or value-added services.

- Conduct market research to understand the potential profitability and customer acceptance of new product lines.

- Invest in research and development to ensure quality and innovation in your expanded product offerings.

Value-added Services:

- Explore opportunities to provide value-added services that complement your nylon products. For example, offering customization options, packaging design services, or technical support to customers.

- Identify the specific needs and pain points of your target customers and develop service offerings that address those needs.

- Communicate and promote these value-added services to differentiate your business from competitors and attract customers seeking comprehensive solutions.

Strategic Partnerships:

- Identify potential strategic partners within the nylon industry, such as suppliers, manufacturers, or distributors, to form mutually beneficial collaborations.

- Leverage partnerships to enhance your capabilities, expand your reach, and access new markets or resources.

- Build long-term relationships with suppliers to ensure a stable supply chain and negotiate favorable terms.

Customer Relationship Management:

- Nurture and strengthen relationships with existing customers by providing excellent customer service, maintaining open communication, and exceeding their expectations.

- Seek customer feedback and actively incorporate it into your business processes and product development.

- Implement customer loyalty programs, exclusive offers, or incentives to encourage repeat business and foster customer loyalty.

Continuous Improvement:

- Regularly evaluate your business processes, production efficiency, and customer satisfaction levels to identify areas for improvement.

- Embrace a culture of continuous learning and innovation within your organization.

- Stay updated on industry trends, emerging technologies, and market dynamics to stay ahead of the competition.

Scaling and diversifying your nylon cutting and sealing business requires careful planning, market research, and strategic decision-making. Evaluate opportunities for growth, adapt to market demands, and build strong relationships with customers and partners. By pursuing these strategies, you can expand your business, enhance your competitiveness, and achieve long-term success in the Nigerian market.

Conclusion

Starting a nylon cutting and sealing business in Nigeria requires careful planning, market research, and adherence to legal requirements. By understanding the diverse nylon types and market demand, creating a tailored business plan, and establishing the necessary infrastructure, you can position your business for success. Staffing, effective marketing, and sound financial management are essential for operational efficiency and profitability. Overcoming operational challenges, embracing innovation, and exploring opportunities for scaling and diversification can drive long-term growth. With dedication and strategic decision-making, you can thrive in Nigeria’s dynamic nylon market and establish a successful business.